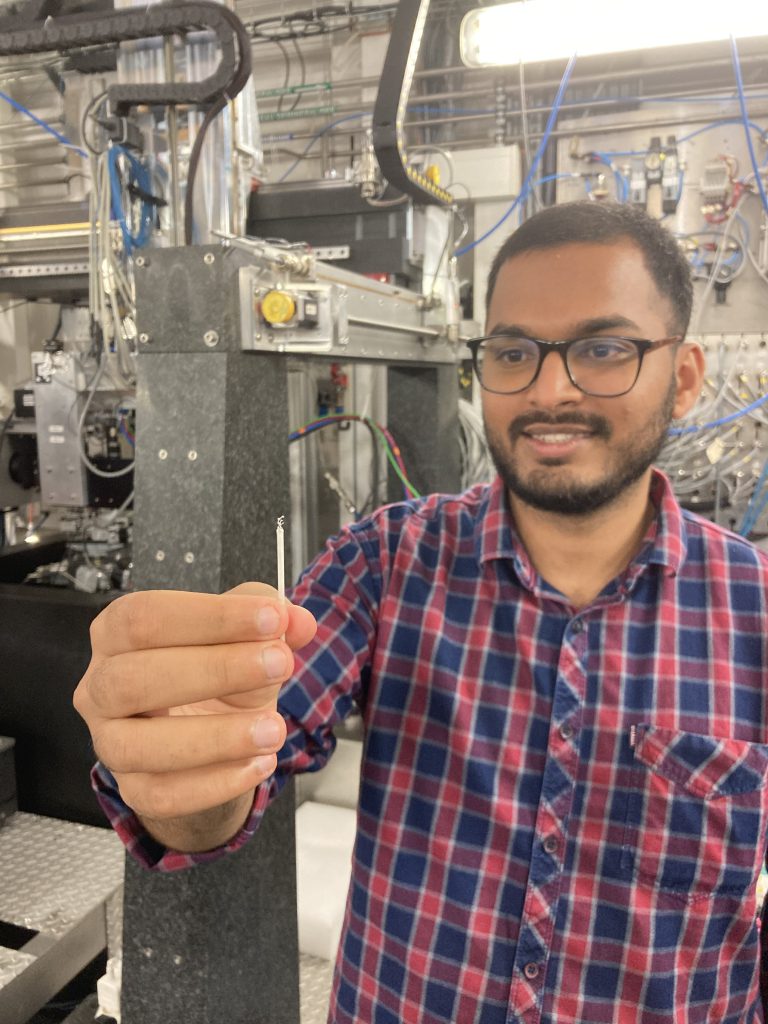

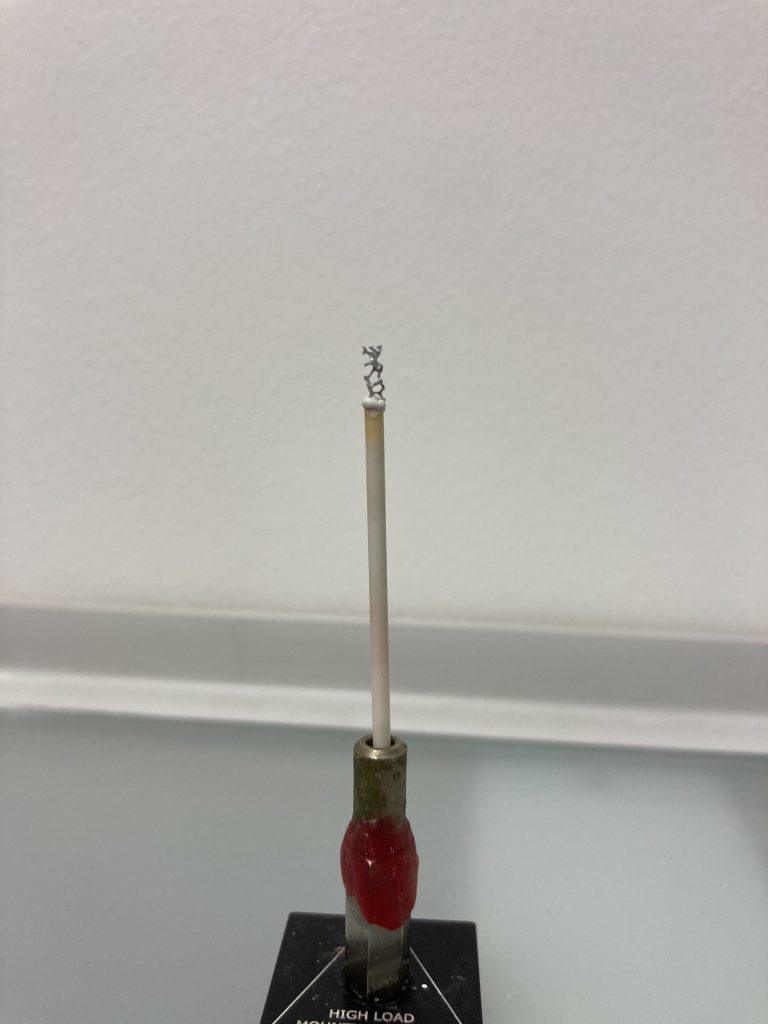

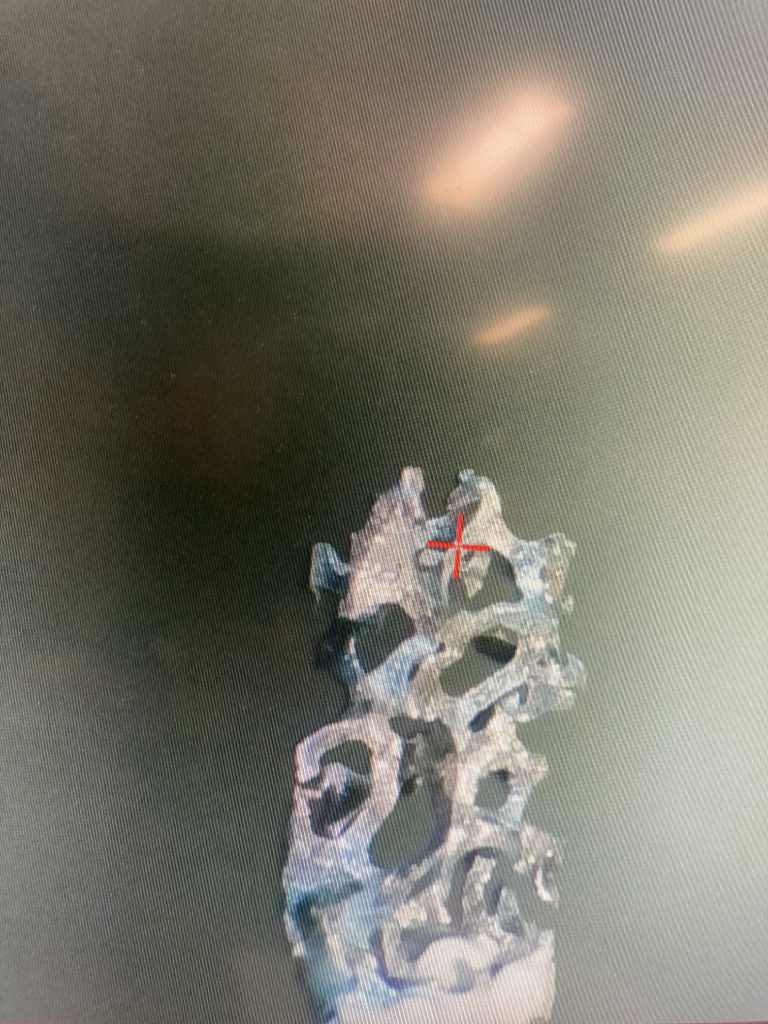

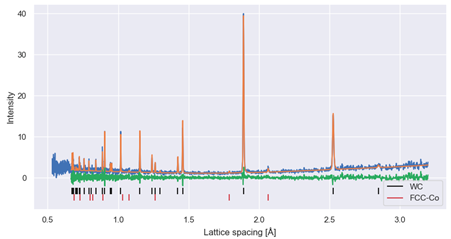

Between 14th – 18th September, Indrajeet, Pär and Johan together with researchers from Lund and Ulm Universities went to Grenoble to conduct measurements at the European Synchrotron Radiation Facility (ESRF). The purpose of the visit was to investigate the microstructural evolution of metallic foams during heat treatment using an in-situ x-ray setup. This is part of Indrajeet’s PhD project, which is part of a joint Swedish-German project funded by the Swedish Research Council. The in-situ experiments were challenging, but the results look promising. Thus, we are confident that you will hear about the results at a conference in the near future.